Maintenance and Repair Log

Maintenance of machinery and equipment is essential so that any issues can be detected in time. If significant problems are to be avoided, these issues must be fixed promptly. A company that often carries out maintenance activities will know of any problems so that they can be fixed.

A proper procedure must be in place to let a company carry out maintenance activities and know what needs to be fixed. The information needs to be saved carefully. A maintenance and repair log can be helpful here.

What is a maintenance and repair log?

This document notes down maintenance activities carried out on a particular asset. It will state whether the asset has been repaired or not.

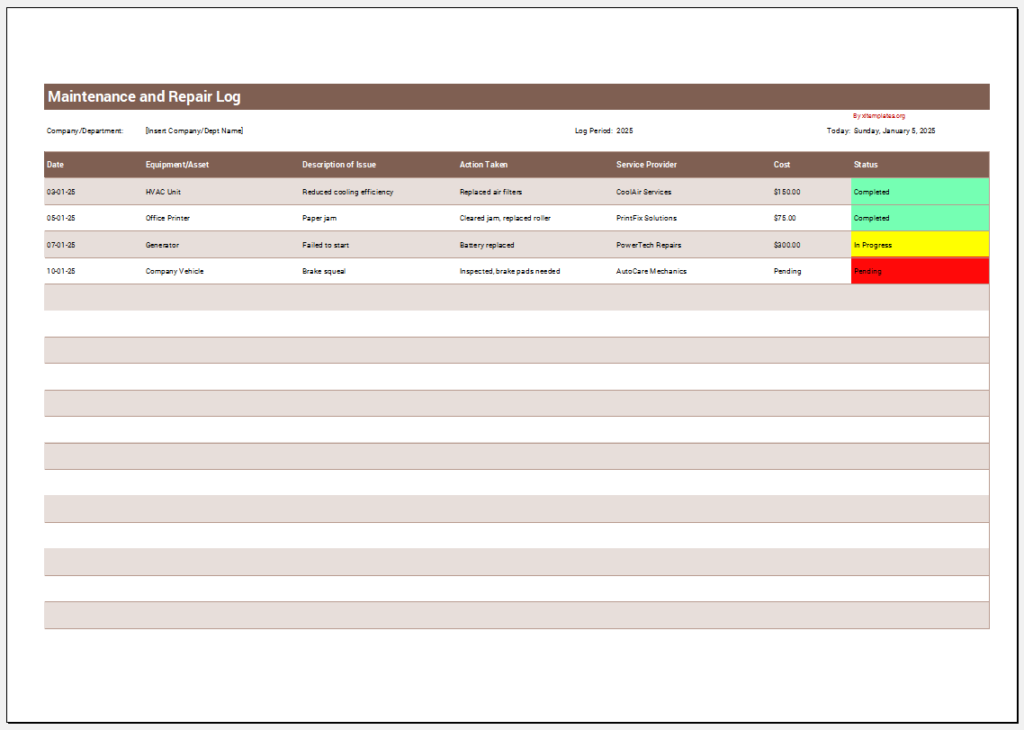

#1

Excel Spreadsheet File [.xlsx]

What does a maintenance and repair log do?

The log lets an organization or company know whether critical equipment is in working order. The document records all asset maintenance tasks so that these procedures can be checked and tracked when needed. The log ensures that no maintenance schedules get missed and that all machinery is checked on time.

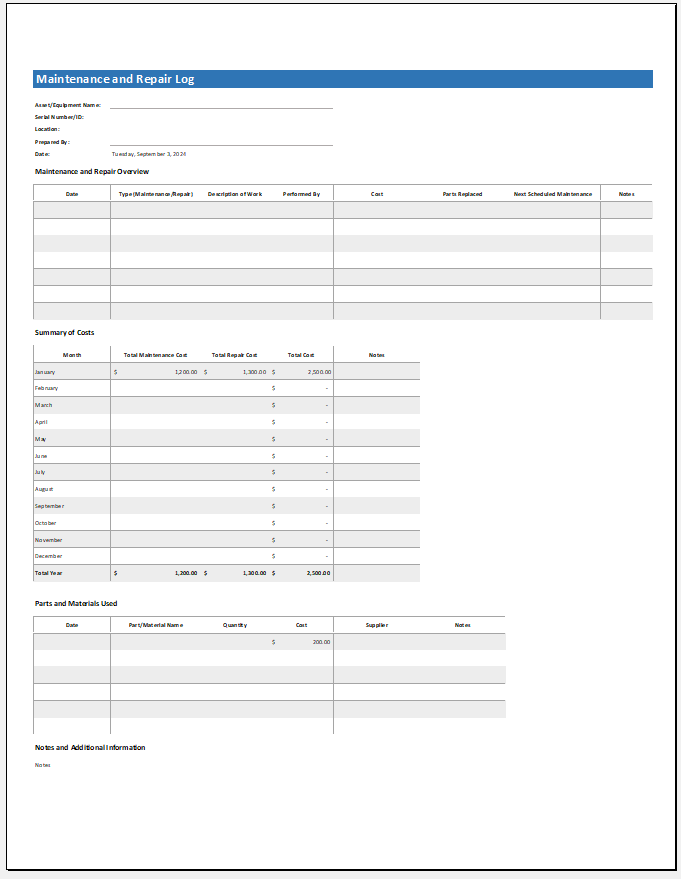

#2

Excel Spreadsheet File [.xlsx]

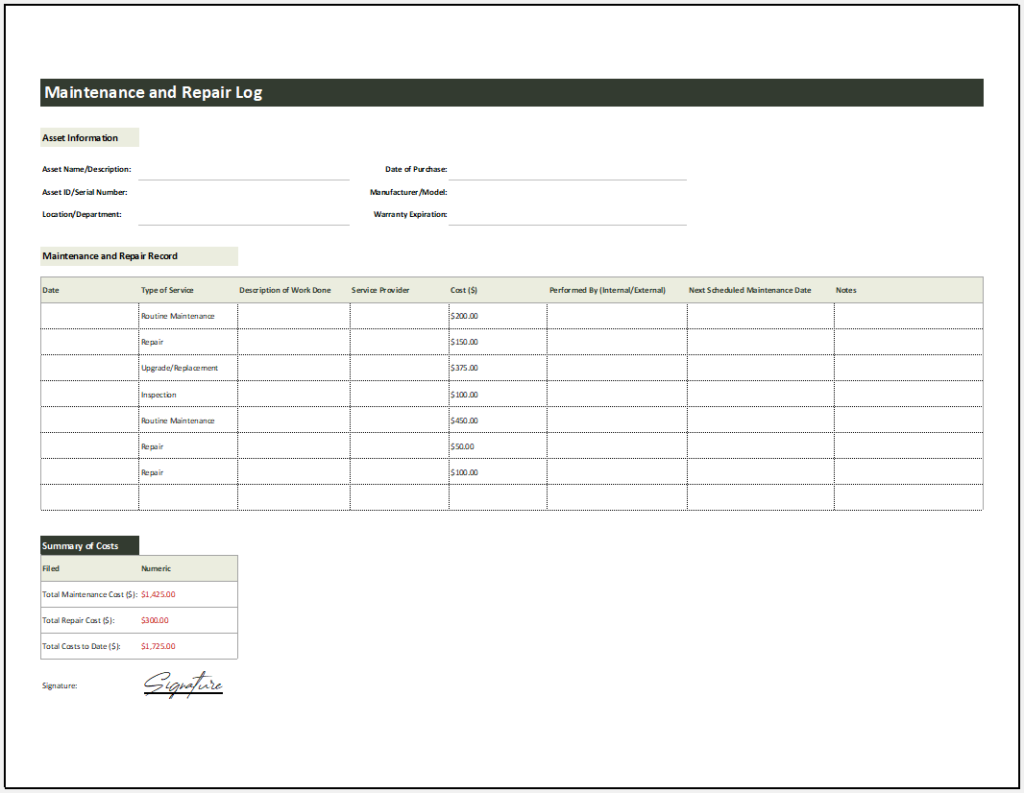

#3

Excel Spreadsheet File [.xlsx]

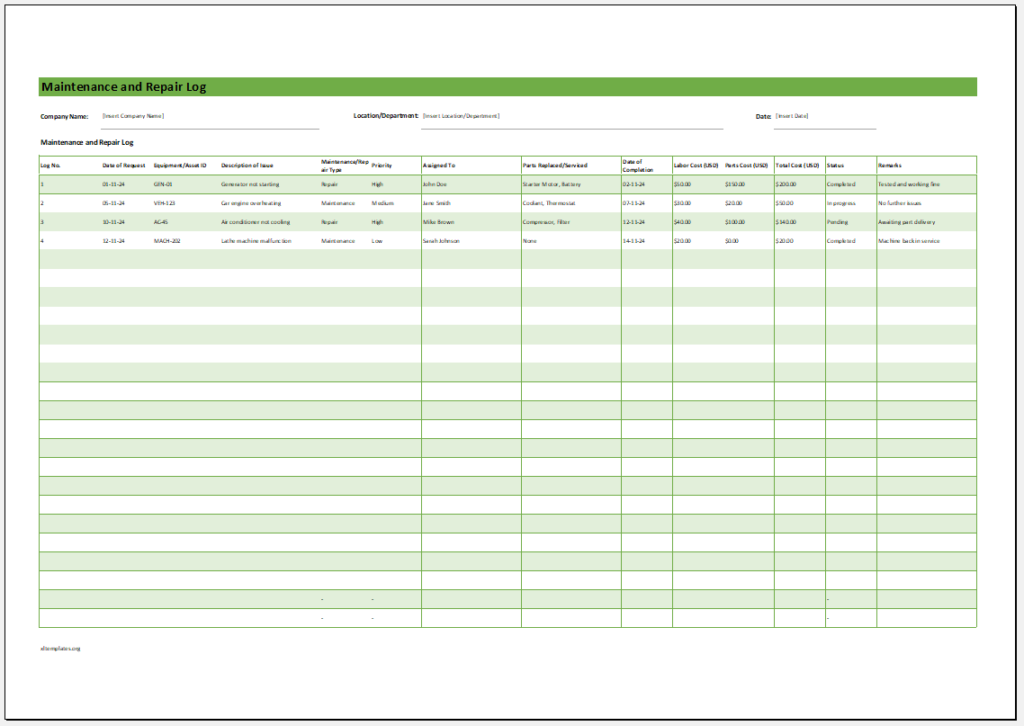

#4

Excel Spreadsheet File [.xlsx]

Creating the log

Every piece of machinery and equipment can have its very own log. If you want to create a maintenance and repair log that people will find easy to use, you can consider the following points:

Decide on the best application:

A maintenance and repair log can be made in Microsoft Excel or Microsoft Word. You can include all the necessary information in a table format.

Details about equipment:

The heading can be “Maintenance and Repair Log”. Include the name of the company for which the log is for. State the details about the equipment, such as the name of the equipment, its serial number, manufacturer, contact details of the manufacturer, date of purchase, date of service, technician, and due date. This information can be included separately.

Details to include on the table:

Create a table that can include details about maintenance and repair. A column for a date should be present so that the date the maintenance occurred can be stated. A column for maintenance description needs to be present to allow one to state precisely what maintenance activity occurred. You can include a column for inventory used and another column for hours spent on maintenance.

A column for validation can state who carried out the maintenance activity. You can even have a column for the date of validation. A column for the next activity due is helpful so it can be known when the next maintenance activity needs to occur.

You may add a column for notes where extra details related to the maintenance that should be known can be included. At the end of the table, you can include an area for additional remarks and another for initials.

It is essential that the document only includes details that are required and need to be known when future maintenance activities occur. Therefore, this information should be added precisely and carefully so that those who need to consult the log will not be confused.

The log helps to know whether the equipment is maintained

A maintenance and repair log is essential as it helps a company know whether all its equipment is maintained and working correctly. Faulty equipment can cause significant problems and injuries; therefore, all equipment must be checked often and maintained.

\The log will make sure that no machinery is left out and that everything is checked and in good working condition when it needs to be used. The log will let one know who carried out the maintenance and repair activity and when this occurred. If the machinery experiences the same problem, the person who carried out the maintenance task can be consulted.

A company will have records of its equipment and what work has been done when a separate log is present for different equipment and machinery pieces. When all machinery is maintained often, it is more likely to be working when needed. In this way, no issues will be present when the machinery needs to be used, helping a company work more efficiently.

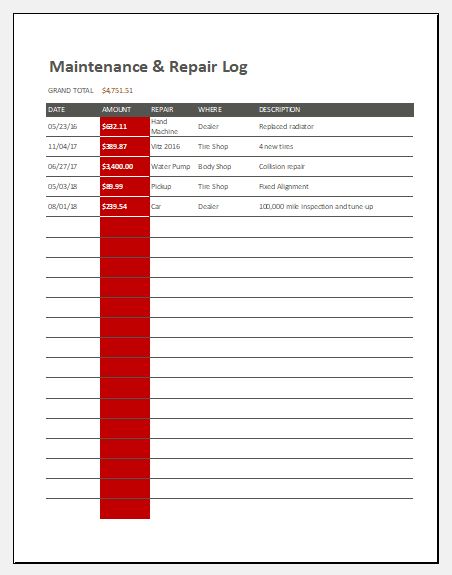

Below is a template of the repair and maintenance log sheet:

Preview

- Monthly Attendance Sheet for Employees

- Student Entry & Exit Log

- Gantt Chart for Smaller Projects

- Behavior Log of Child for Schools

- Loan Repayment Tracker

- Product Sales Tracker Template

- Debit Memo Template for Excel

- Winter Attire Inventory

- Financial Projections Worksheet

- Employee Absence Tracker

- Weekly Sales Report Template

- Budget Vs Actual Statement

- Remote Work Attendance Tracker

- Mileage Expense Report Template

- Fitness Calendar Template

← Previous Article

Departmental Store Inventory SystemNext Article →

Employee Absence Tracker Calendar

Leave a Reply