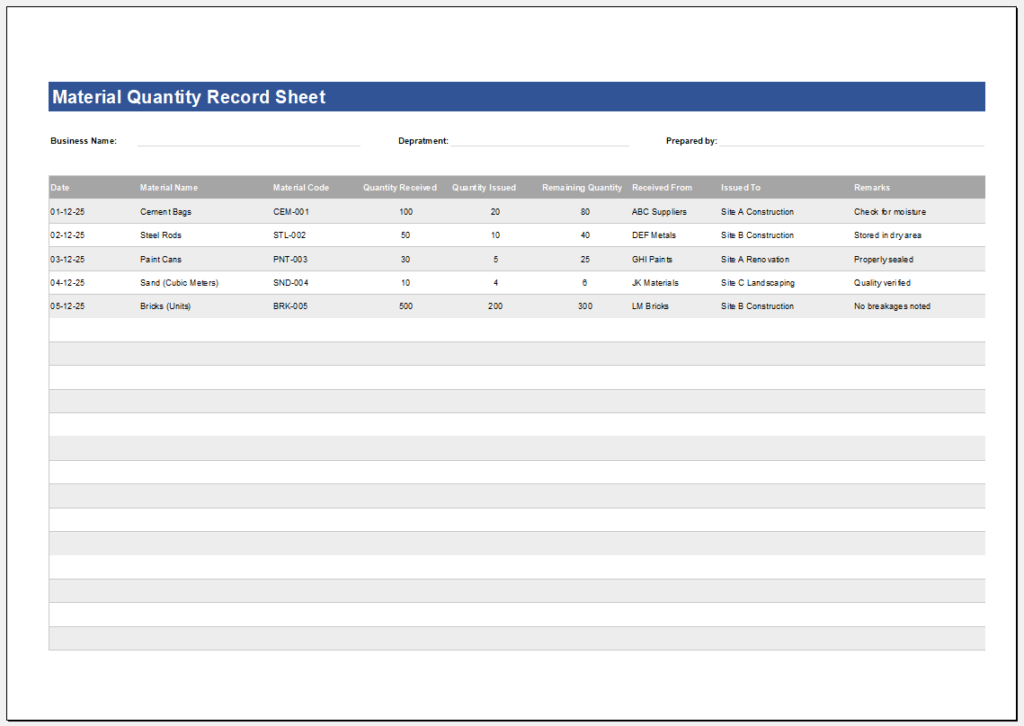

Material Quantity Record Sheet

All functions in an industry need to occur ideally. Everything must be analyzed carefully so that operations succeed. The material used in producing products needs to be carefully audited. When this is not done, it can lead to errors and the production of low-quality products. A material quantity record sheet is helpful here.

What is a material quantity record sheet?

The engineering department often creates a material quantity record sheet. It is based on the expected material that must be theoretically employed within the production phase. There will also be an allowance for some scrap.

Importance of a material quantity record sheet

A material quantity record sheet records the number of different materials present. Manufacturers and staff can know how much material is available, which one is available, etc. Therefore, the production of goods can occur efficiently.

Tips to create a material quantity record sheet:

When making a material quantity record sheet, it is essential to do it carefully to avoid errors. The following tips can be kept in mind here:

Microsoft Excel:

It is important to select an application to create the sheet. You have to choose the right one if you want it to save and calculate everything carefully. Microsoft Excel is good here. Tables can be made, and calculations can occur quickly.

Heading:

The sheet is professional and formal. It would be best if you created it like this, keeping the point in mind. A heading should be included. It will be a “Material Quantity List” or something similar. The heading allows everyone to know what the document is about.

Table:

You will create a table in the application. If you have the proper headings, a table is easy to fill in and simple to read. Please ensure that whoever needs to fill it in or read it will not find the activity challenging.

Item name:

The first column will be for the item’s name. It will be precise, including its name only.

Description:

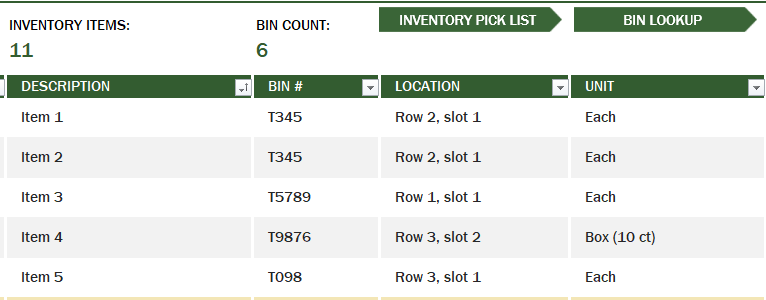

It is a good idea to add a column for description. Here, the person filling in the table will give a brief description, allowing everyone to know what the material is and its purpose. Make it short. You can state the product ID, name, description, and category all in separate columns if you want.

Quantity:

This column will state the quantity of the material. Only tell the quantity here without adding any description.

Unit cost:

Include the cost of the single material. This will help management determine how much is needed to make the product.

Total:

It is important to tell the total cost of one type of material. One needs to know the expected amount. You can include a column that describes where the material needs to be brought from. This will make it easier for the people purchasing the stuff to know where to go.

Prepared by:

At the bottom, state who prepared the table. This information is necessary when records are being checked, and management also requires it.

Signed by:

A signature gives any document an authentic touch. It confirms that whatever has been stated above is true, as the person who has signed it will know who to contact if any issue occurs later.

All items:

The table will include all materials needed to create a single product. It will be helpful to make a different one for every item that has to be produced. This one will be more useful for everyone.

Draft it carefully

From the above, you can tell that the quantity record sheet is important. It should be made carefully and clearly. It should be simple to fill in and read by all involved in this business area. The sheet may probably be kept as a record and must be filled in carefully.

Any mistakes can lead to errors that can penalize the people involved. The above points can be kept in mind when making the sheet.

- Product Sales Tracker Template

- Debit Memo Template for Excel

- Winter Attire Inventory

- Financial Projections Worksheet

- Employee Absence Tracker

- Weekly Sales Report Template

- Budget Vs Actual Statement

- Remote Work Attendance Tracker

- Mileage Expense Report Template

- Fitness Calendar Template

- Project Gantt Chart

- Daily Attendance Tracker for an Individual Employee

- Overtime Hours Tracker Template

- Vacation and Leave Tracker Template

- Departmental Expense Report Template

← Previous Article

Weekly Appointment Sheet TemplateNext Article →

Office Expense Budget Worksheet